HOOS LIFTING EFFICIENCY – ВЫСШАЯ СТУПЕНЬ РАЗВИТИЯ ТЕХНОЛОГИИ

Особенности развития новой технологии

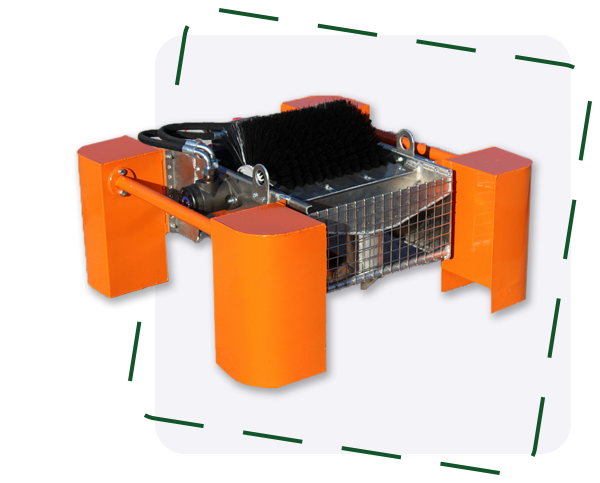

HOOS – это высшая ступень развития Технологии добычи нефти с использованием олеофильного скриммера-нефтесборщика.

Технология дополнена полнофунциональной операционной системой, обеспечивающей онлайн- сообщение, дистанционное управление и оптимизацию добычи, что способствует развитию Ваших цифровых решений в сфере нефтепромысла.

Технология была разработана с уделением первоочередного внимания оптимизации добычи, эффективности энергоиспользования, высокой надежности и заботе об окружающей среде.

HOOS – это новая технология искусственного подъема нефти на месторождениях с запасами средней и тяжелой нефти. В отличие от традиционных технологий, она заменяет вертикальную перекачку – вертикальной транспортировкой.

Это нововведение позволяет технологии:

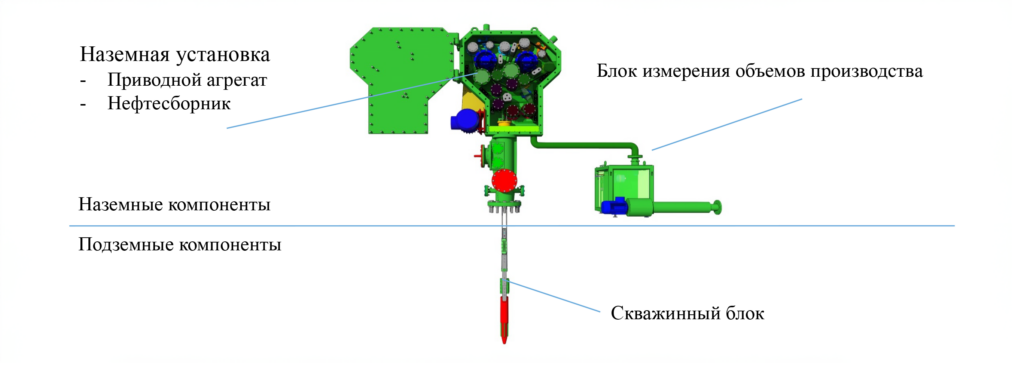

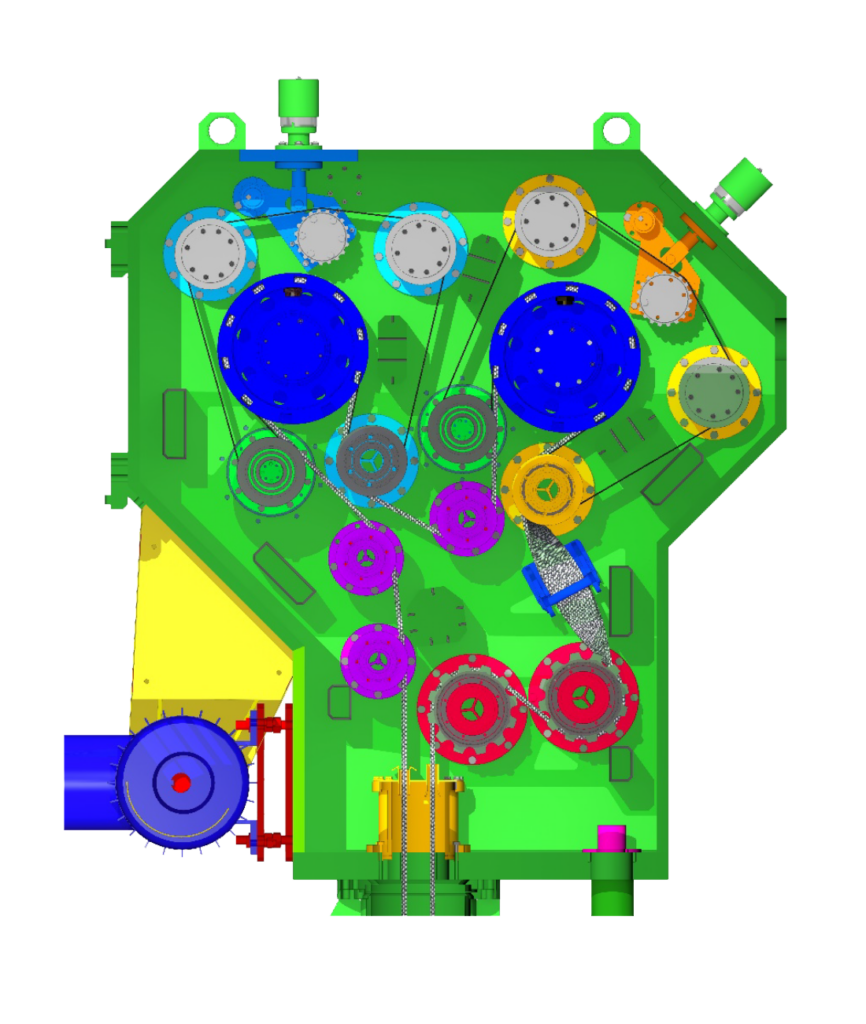

Единица поверхности – это совокупность специализированных различных систем:

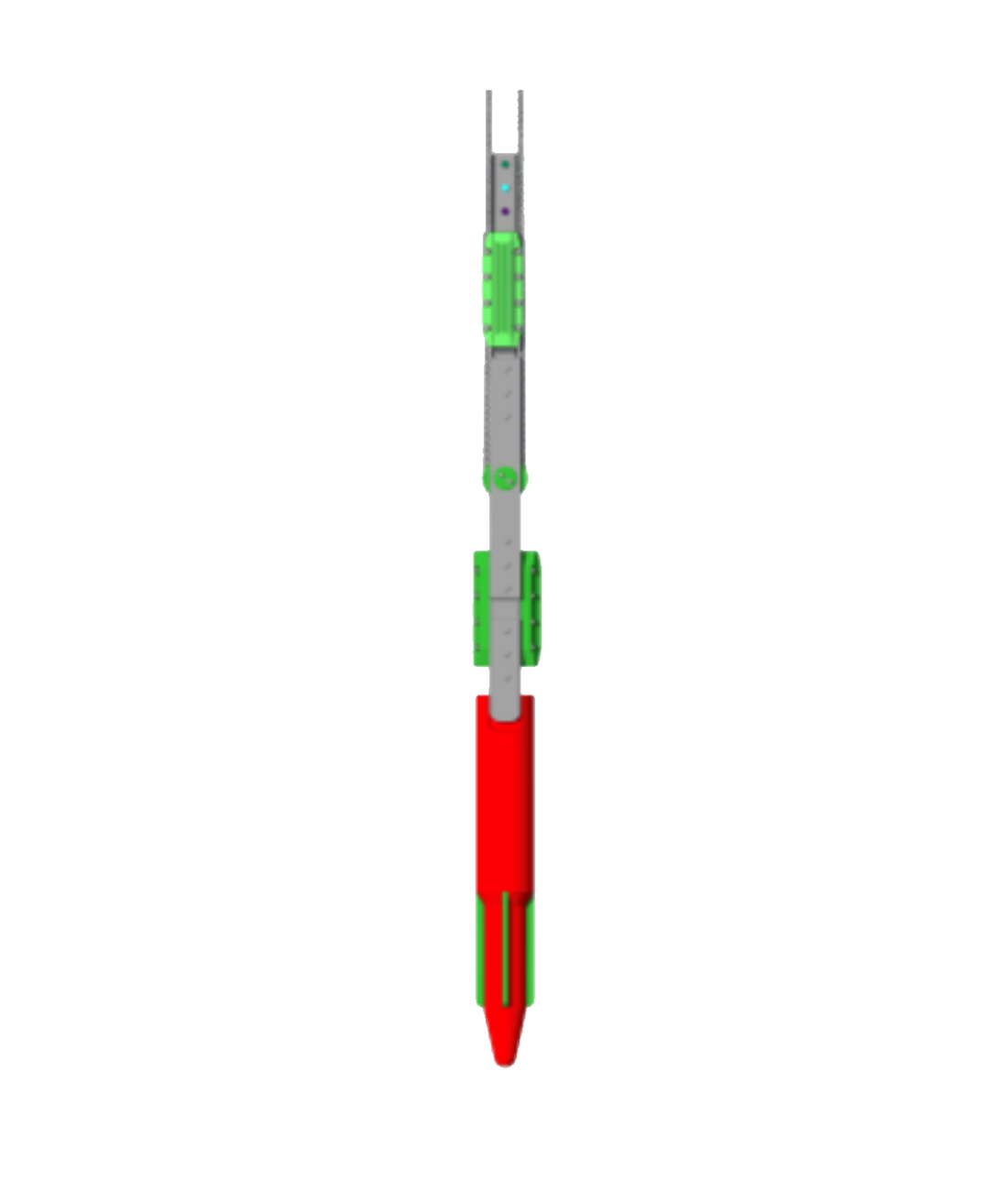

Технология скважинной установки:

Полноценная Операционная Система предназначена для:

• Запуск и остановка

• Оптимизация добычи или потребления

• Отчет о состоянии ремня, добычи и установки

• Диагностика добычи

Датчики ATEX и Автоматическое отключение в случае неисправности.

Автоматическая настройка скорости ленты для повышения производительности и Управление энергопотреблением

Настраиваемые уровни порогов чувствительности.

Основной механизм: ход насоса * рабочий объем цилиндра и Дублирующий механизм: разность уровней

Измерительный блок может быть настроен исходя из характеристик скважины

Данные можно автоматически передать другим ИТ-системам

ЛУЧШИЙ ВЫБОР ДЛЯ ДОБЫЧИ ТЯЖЕЛОЙ НЕФТИ

Лучше всего подходит для тяжелой нефти и песчаной нефтедобычи, скважин со статическим уровнем до 4000 м. Погружаемость до 10 м ниже уровня.

Отчеты о добыче, энергопотреблении и других параметрах в режиме реального времени. Невосприимчивость к негативному воздействию газа, CO2, SO2.

С повышением вязкозти нефти эффективность значительно снижается. Технология HOOS способна повысить эффективность нефтедобычи.

На 400% больше добытой нефти, чем при использовании традиционных технологий ранее используемых на тех же скважинах.

Незамедлительная отдача после процессов усовершенствования и решение проблемы наличия песка в скважинах.

Сокращение всех затрат на 65% и сокращение потребления энергии на 75% по сравнению с традиционной нефтедобычей.

Значительное снижение необходимости в реконструкции скважин и невосприимчивость к наличию воздействия негативного газа.

Значительная и быстрая позитивная отдача. Количественная эффективность и быстрая окупаемость при добычи нефтескважинах.

Экономия до 90% потребления электроэнергии.

Увеличение чистой добычи до 200%.

Установка весит 1,2 тонны и произведена с использованием нано-технологий для достижения соответствующей эффективности.

Отсутствие металлолома во время работы.

Использование больших электродвигателей.

Экономически неэффективен в малодебитных скважинах.

Трубы и насосные штанги изнашиваются и подлежат замене – это означает, что тонны металла должны перевозиться и обслуживаться.

В производстве установки используются тонны чистого металла.